You have a headache to think of how to upgrade your product image to competitors, instead of using an old iron to create images on materials, give up that idea. but instead an information investment with a quality heat press machine. It is known that the heat press machine uses heat and pressure to print the design onto the substrate.

In addition, they can also apply graphics on a variety of other materials such as fabric, leather, ceramics, and many more. In general, the first design was printed on thermal transfer papers and specialized for the use of solvent inks. This ink is designed to transfer from the floor paper items when heat pressed. A few stubs to get you the gist below. Come find out with us.

1. What is the heat press machine?

A heat press machine is known as a device whose design moves from graphic design on the substrate. Most people use heat presses for printing jobs. It will replace the use of other design technologies such as screen printing or sublimation. Moreover, heat presses help you transfer artwork or personal designs on clothing materials, garments, cookware, shirts, hat brims, wood, metal, memo blocks , jigsaw puzzles, letters, tote bags, mouse pads, ceramic tiles, porcelain plates, mugs, t-shirts, and more.

In general, you can picture them having an electronically heated metal surface called a platen. Because when you create a large part of the pressure on the heating surface, along with controlling the heat and time appropriately. From there you will visualize how the process or its dynamic takes place. The use of heat press machines will create high profits for businesses and individuals because they will produce designs on each material perfectly and operate at a very high speed that will help businesses finished product production. In fact, a heat press machine is a very affordable tool, no matter how much money you spend, no matter how fast or slow you get from the heat press machine a significant amount.

Besides, the heat press machine is a graphic design device that you can easily operate. Since they are designed to be portable, they are very convenient to store in a corner of the store. But it should be noted that although the heat press machines are cheap and bring high productivity, to ensure the quality of the product should carefully consider each part of their structure.

As for other printing technologies like screen printing, they only create rough texture on the shirt, and only use it when printing multiple colors but heat presses will provide a smooth graphic that can be easily printed. series of special effects on the material by means of a heat press machine. In addition, heat presses will operate at very high temperatures close to 400 degrees Fahrenheit and can be effectively used in conjunction with other printing techniques. Especially combined with inkjet techniques.

2. How does the heat press machine work?

To explain how heat presses work, here we have a look at the process that has left many wondering how it works. You must understand that heat presses use the heat and pressure that a part of their equipment generates.

Thanks to such heat and pressure, it makes it possible to print graphic designs onto materials that are easy to color on t-shirts, plates, jigsaw puzzles, mugs and other receptive items with a heat press machine. On the other hand, heat presses can be operated manually or automatically to produce higher quality. However, if the heat press machine operates automatically, only a portion of the operator's power needs to be applied to it. Nowadays, technology techniques have also improved a lot.

In order for the heat press machine to work at full efficiency, it is necessary to make use of transfer paper and sublimation ink. First you need to print your graphic design onto good quality transfer paper vinyl. And make sure the transfer paper surface must use a smooth surface and waterproof surface.

As a next step, heat the press to ensure that the ink is printed on the materials that must adhere to the fabric. In fact, this type of heat press machine is a must-have for any fabric design or other form-related business. But here is also some basic information that you need to know before putting this type of press into operation.

3. Benefits of heat press machine

Save time based on the heat press machine

If anyone has used a heat press machine, the heat press machine applies at a fast speed so you will have less preparation of steps, less curves. As you get used to this machine, you will add some skill to yourself by using a digital timer. But the timer also depends on the fabric you are using and will beep when the process is finished. Especially during the working process of the machine in operation, you can transfer other materials in. This makes printing faster and more efficient.

Pressure consistency of heat press machine

One of the key factors when starting a transfer press for fabric is pressure. With old irons, measuring pressure is not easy. Thanks to this factor, manufacturers need a certain amount of pressure. On the contrary, if you accelerate the speed of the pressure, all the materials through the machine will be burned. For a perfect pressure, look at the difference between the quality of the product used after many months and years.

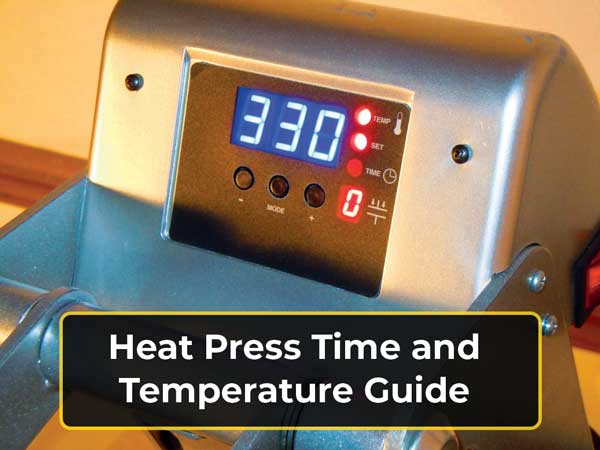

Temperature setting of the heat press machine

In fact, besides the pressure setting, we also need the temperature on each material such as cotton, polyester, spandex and blended fabric. However, the dial on the iron clicks between linen, cotton, wool, and silk. And they do not have a specific temperature on how hot the iron should be. The flip side of not knowing the exact temperature can also lead to melting and scorching, or areas that aren't hot enough for the level of adhesion to the materials to last longer. For heat presses, the temperature can be set manually and this ensures that the temperature remains constant for most of the products.

Enlarged pressing space

For businesses, receiving hundreds to thousands of orders every day if the brand is quality. Especially with frequent printing, a day pressing images in different stages can be a complicated affair. Usually the sizes of that 5x3 inch iron are a wide end model and it might work when pressing the stage switch but doing so they will be ideal for the time.

Don’t waste money

The heat transfer element of the heat press machine will help to partially decorate the garment and save printing costs and time with small orders. Almost the unit prices for clothing are unprecedented in the printing industry. So that allows customers who have ordered some items in stores and they will not be inflated in price.

Keep cleaning your space working

The special feature of using a thermal transfer t-shirt printer is that it is less messy than other presses, because they inherently use solvents and dyes. Thanks to the heat transfer machine, the product will not be damaged due to ink spills.

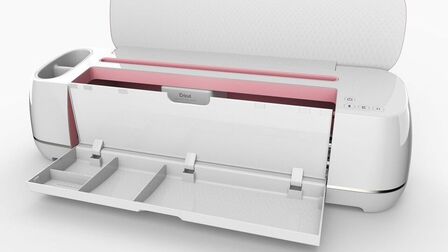

Let’s have a look on a very cool Cricut product heat press machine

With Cricut's original purpose of helping people to work creatively through the use of products we provide tools to make user work schedules convenient in modern life today. And when we came up with the concept of building the first cutting machine, a vision of a simple tool with the potential to completely change the way people think about manufacturing and design.

This helps Cricut continuously innovate the way it looks and create new machines, materials and tools that give meaning and uniqueness to the user. Along with a team of enthusiastic employees in creative work, we believe that we will always update and change to be more suitable for consumers.

Here is one of the products that we would like to introduce to you. Cricut EasyPress 2 are typically 12" x 10" (30 cm x 25 cm) and are great for large t-shirts, sweatshirts, banners, blankets... Besides, they offer great heat transfer results Well, along with the thermal plate design with ceramic coated surface they are compatible with all Infusible Ink™ products and ferrous materials.

In addition, with 400℉ (205°C) adjustable heat for use. This type of juicer gives you fast, effortless use and longer service life, but they also take the guesswork out with upgraded factory-defined time and temperature settings. When you hear a beep, the pressing process is complete. Overall, the Cricut EasyPress™ 2 is lightweight, portable, and easy to store in the corners. Beginners need not worry as they are easy to learn and simple to use.

Conclusion

In a nutshell, a heat press will basically refer to a tool that presses artwork or images onto materials. You can print on t-shirts or whatever paper you want, and the quality is still perfect. For the heat press machine, it can produce high pressure and also set high temperature to effectively and long-lasting your logos or images into the product.

Investing in a heat press machine now is a necessary condition for those who want to have beautiful works. Thereby, the information about the benefits of heat press machines will give you all the information you need to trust and buy a product for yourself and your business. Thank you for being part of our fans.